Artistic Design, Manufacture, and Embellishment of Premium Firearms

Gunsmith and engraver Damien F. Connolly is from Mittagong, NSW, Australia. Much of his miniature firearm work is so small that it requires the use of a microscope for the finer details.

From Making Surfboards to Fine Gunsmithing and Engraving

Damien F. Connolly has spent a lifetime developing the skills to make objects of function and beauty. At eight years old, he was already using a knife to carve animals from wood, and making model guns. By his teens, Damien was making money shaping surfboards after school. At 17, he was working for Bernard “Midget” Farrelly, the 1963 World Surfing Champion, and top surfboard maker. Damien was sanding his premium boards, and was soon entrusted with one of the most demanding jobs—applying the fiberglass finish.

Once he finished school, Damien trained as a carpenter, where he could easily find work. However, at just 21 years old he started making muzzle loading rifles, and stayed self-employed with that work for over 33 years. Damien is completely self-taught, and combines his natural artistic talent with skills honed over the years. This has allowed him to constantly take on new challenges.

For example, in 1979 he began to experiment with engraving. Damien wanted to control all aspects of his gun and knife projects, from raw metal to the finished work of art. In between gunsmithing jobs, he also developed an interest in race cars. As a result, Damien gained specialized knowledge in welding, carbon fiber component molding, and other techniques. This largely owed to his experience as a driver and race car fabricator.

While tradesmen can point to large buildings or bridges they’ve worked on, the craftsman who works in miniature might be able to display an entire life’s work in one room. Perhaps even on one or two tables. In truth, miniature craftsmanship is judged by quality, not quantity. People wishing to commission high quality craftsmanship are generally more interested in focused results than a large volume of work.

Throughout his life, Damien developed a vast array of new skills—perfecting each as he went. He’s proven himself a problem solver, continually adding new skills to his mental library. Additionially, his in-house approach to craftsmanship has resulted in a high level of integration between the artistic and functional design elements of his work.

As an example, one project for which Damien can be justifiably proud is the restoration and engraving of a Colt single-action Army revolver. The piece was for an Australian gun collector. Originally manufactured in 1878, the firearm was still in mechanically excellent condition. However, Damien restored the pistol from its “rusted relic” condition to “better than new.” He then engraved the pistol with a large Victorian scroll specified by the client. The grips were carved by Damien in high relief.

The background for the grip was checkered between the design elements in a tiny 50 lines-per-inch diamond pattern. Damien also built a case for the revolver, which features extremely graceful and delicately inlaid scrollwork around the Colt name. Damien’s photo section details the process of creating such a work of art. His work is more than a specialized craft, it is the product of many years of dedication, and the steady development of a range of skills.

Working Smaller Provides New Challenges

One of Damien’s more recent projects took his skills in a new direction once more. After years of building and engraving full-size guns, he completed a 5-year project of smaller scale. This was a 1/5 scale flintlock Kentucky long rifle, complete with display case. While most miniature gunsmiths work at 1/2 to 1/3 scale, functional pieces at 1/5 scale are extremely tiny. At that size, they actually possess just a little over 1/5 the mass of a 1/3 scale weapon. The challenges of working at this scale increase exponentially. The parts are so small that almost all of the work had to be completed under the lens of a microscope.

Almost 2,000 hours were invested in this tiny masterpiece, and the finished gun weighs only 1 oz. It’s accompanied by a beautiful wooden presentation case, lined in beige pigskin suede, and complete with accessories and fixtures for display. In keeping with his in-house approach, everything from the metalwork, woodwork, and engraving utilized the skills that Damien had gained over a lifetime.

A close view of the miniature Kentucky long rifle barrel, which is just over 9″ long, has a bore of .098″, and is rifled with 7 individually broached grooves.

Building the 1/5 Scale Kentucky Long Rifle

If you were to hollow out a pencil and leave a decent wall thickness, this 1/5 scale Kentucky long rifle would easily slide inside—all the way up to the lock! Remarkably, it weighs just one ounce. That is 1/125 of the weight of the real thing, just as the laws of cubic measurement demand. By way of comparison, at 1/3 scale it would weigh over 4.6 ounces. Damien’s goal was to work at the smallest size possible, while still producing a piece that was indistinguishable from a normal size firearm—apart from its size, of course.

With regard to construction, Damien built this piece entirely out of stainless steel, with various grades chosen for each application. Additionally, he used a unique treatment for the woodwork in an effort to create a piece that would last ages. No concessions or simplifications were made to accommodate working at this scale. Instead, smaller tools were built and used. A large amount of the work was done using the 9x magnification provided by a microscope on a “telescopic swing arm.”

The telescopic swing arm allowed Damien to use the microscope at all workstations. Having that tool provides the field of view necessary to enable the accurate use of files. The engraving was executed at between 15x and 25x, using specially sharpened versions of the standard engravers tools.

All told, Damien spent 600 hours just making the drill/mill for this project. Along with the countless hours planning and drawing, this project consumed no less than 2000 hours of Damien’s life over a five year period. He says this job crystallized in his mind the secret of doing one’s best work: “Try really hard and take a long time.”

See Damien’s photo section for more details on the rifle and case. For those interested in a far more detailed account of the project, Damien also prepared an article on the subject.

This picture shows the extremely fine natural striping—or fiddleback—in the curly maple stock. Notice the delicately filed fences, where the tang transitions onto the barrel. Also, take note of the .012″ diameter pins through the stock, which retain the trigger guard in the traditional manner.

A Look Inside Damien’s Shop

Damien’s work utilized two shops: one filled with full-size machinery, and the other dedicated to miniature work. The latter is equipped with small power and hand tools. The drill press was designed and built by Damien himself.

Building a Custom Made Drill Press

In order to build the miniature Kentucky long rifle, Damien had to buy a motor, spindle bearings, a drill chuck, and some bolts. Most impressively though, is the fact that he built his own 16-speed, 1,000-28,000 rpm tilting head drill/mill. Damien built it entirely from bar stock. Features on Damien’s custom drill/mill include micrometer adjustable quill feed and depth setting, and true Vernier depth stop adjustment. A counterweight offers adjustment from a weight assisted drilling feed to a “sprung” return. All non-painted metal for the rifle was a grade of stainless steel appropriate for the component.

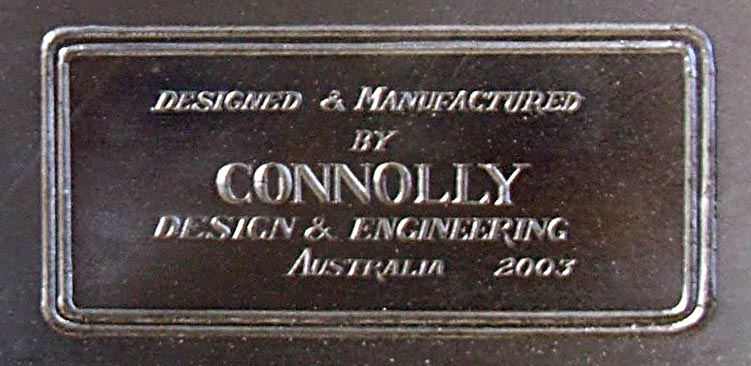

When the drill press counterweight is at neutral position, it has feather-touch sensitivity through the moment/index adjustable lever, and central handwheel. A Connolly designed collet chuck holds 1/4″ straight shank cutters, while the table has tapered gibs and fully adjustable stops. The moving jaw on the vise comes under downward pressure as clamping force is applied. This ensures accurate and square clamping of small items held in the upper edge of the jaws. Over 600 hours were logged in the design and construction of this drill press. The picture below shows the maker’s plaque engraved on the base plate.

View more photos of Damien Connolly’s work, with detailed descriptions courtesy of the craftsman.