Giant Models or Undersized Construction Equipment? Working Models in 1/2 Scale Blur the Lines

Recipient of the 2012 Joe Martin Foundation Lifetime Achievement Award

Fred Heim is not a giant person. He is standing next to his 1/2 scale Peterbilt tractor and trailer, which is considerably larger than most of the miniatures typically featured here. Fred built many large wooden models like this one just for the fun of it!

Introduction

By Craig Libuse

One of the main functions of the Joe Martin Foundation is to honor craftsmanship at the small end of the size scale, but what exactly qualifies as small? In the model making world, choosing scale is one of the first decisions made. Ultimately, the chosen scale might be determined by the equipment one has, the size of your shop, or the cost of materials—among other factors. Most people settle on a scale that allows the finished model to be easily handled, while still possessing a great level of detail.

However, others might choose the smallest possible scale based on their ability to produce the smallest part in a model at that scale. Fred Heim, on the other hand, chose a scale that almost no other modeler works in, especially those modeling something as large as construction equipment. After all, who builds in 1/2 scale? Even at half-size, these pieces are huge! However, the advantage is that almost all of the functions can be made to work realistically. In fact, in some cases they are still large enough for an operator to climb inside and run them!

Now, on the surface many of Fred’s models may look like metal; however, the majority of the parts are made from wood. There are some exceptions, as certain parts needed to be made of metal or even fiberglass to be functional. Fortunately, Fred spent many years as a boat builder, which prepared him for model building. There is almost no shape he cannot build in wood. Having built large wooden boats over 30 feet long, Fred also had the shop space and tools to handle these big projects.

Fred’s lifetime interest in construction equipment came to life in these models, which are some of the biggest operational wooden models we’ve ever seen. Compare these to the trucks and trailers built by Joe Enriquez in 1/87 scale to see two extreme ends of model making (in terms of scale, that is). Fred thinks BIG! Below are two articles on Fred and his models. They provide great insight into his thought process, and the construction that followed.

Fred stands next to his 1/2 scale Cat excavator, which has been loaded onto his 1/2 scale Peterbilt tractor and trailer. The models are ready to head off to a show. The Rogers drop-deck trailer is accurately scaled in aluminum. It has mahogany deck planks that were made from plans provided by the Rogers trailer company themselves.

Duplicating Form and Function

Model Maker Excels at Going Large

By Jim Angell

(Originally published in Caterpillar’s official magazine, Cat Folks, March 2008. Reprinted with permission here.)

Model making has always been an art form as people strive for the most realistic duplications, usually on a reduced scale. But for one Caterpillar enthusiast, Fred Heim, modeling is on the big scale as half-scale replicas—including Caterpillar products—are created out of wood.

Heim, 68, a woodworker and retired boat builder from Marlborough, Massachusetts, has been making things out of wood since he was 10, but found his niche in model making when he went large with his creations. The first half-scale model was a Peterbilt 379 that Heim can drive pulling a 26-foot dump trailer. But it wasn’t until he needed something to go on a replica 60-ton gooseneck trailer for the truck that Heim turned his attention to yellow iron.

“I needed something to put on it,” Heim said of the empty trailer. “So I started looking at and taking pictures of Caterpillars. When I was young, everything was yellow, and the equipment my father used on the roads in Maine was all Cat.”

A D8R track-type tractor was the first to get captured in mahogany. Why mahogany? According to Heim, the wood is very durable, is easy to work, and takes a great finish. Later came a 345C L hydraulic excavator, and a remote-controlled 980H wheel loader.

Heim averaged seven to eight months building each Cat replica, but admits the 345C L and D8R were easier to recreate than the 980H. “Wheels are always a problem,” explained Heim. “If you don’t have the proportions right, you can easily mess up, and that’ll cost you a lot of wood and time.”

While Heim didn’t say how much money he has invested in his hobby, it is considerable. But that still doesn’t mean he would sell any of them.*

“I’m not building these to sell. When I get in the shop, my mind gets going. I just love doing this stuff,” he said. “I do about 10 model shows, fairs, or special displays per year. They’re works of art and should be seen. They would be perfect in a Cat museum.”

*Since this article was written, Fred decided to part with some of his models to the right buyer.

—Jim Angell

Magnificent Obsession: Fred Heim’s Half-Size Universe Creates Big Buzz

By James A. Merolla

(Originally published in Construction Equipment Guide, October, 2007. Reprinted with permission here.)

Fred Heim does something that no one in this country does. And he does it as well as anyone could do.

Heim, 68, a woodworker for 58 years, makes exact replicas of popular earthmoving vehicles. These include: a Peterbilt 379 pulling a 26-foot Hill dump trailer, a Cat D8R, a Rogers 60-ton drop-side goose neck trailer with air suspension and fully functional hydraulics, a Cat 345C L excavator, and a radio-controlled Cat 980H wheel loader. All half-size.

Not a miniature, not a shelf model, but actual working vehicles with engines, carved out of mahogany, aluminum, plastic and fiberglass—and all to exacting specs 50% smaller than the real machines they honor.

Heim’s creations have themselves created a world of buzz at machine shows and museums over the past four years. His extraordinary replicas have been seen at trade shows, toy conventions, in parades, at classic and antique machinery events from Indiana to Maine, and even the September grand opening of Joseph Equipment Co. in Manchester, NH. He’s been featured in several videos, including the TV news show Chronicle in Boston. They are masterpieces of museum quality.

Once seen and touched, Heim’s mahogany marvels draw hundreds of people away from whatever they happen to be looking at of ordinary size.

Fred’s remarkable 1/2 scale Cat wheel loader. The rubber strip seen on the center of the tires helps prevent damage to the wooden treads, while also providing traction and a quiet ride.

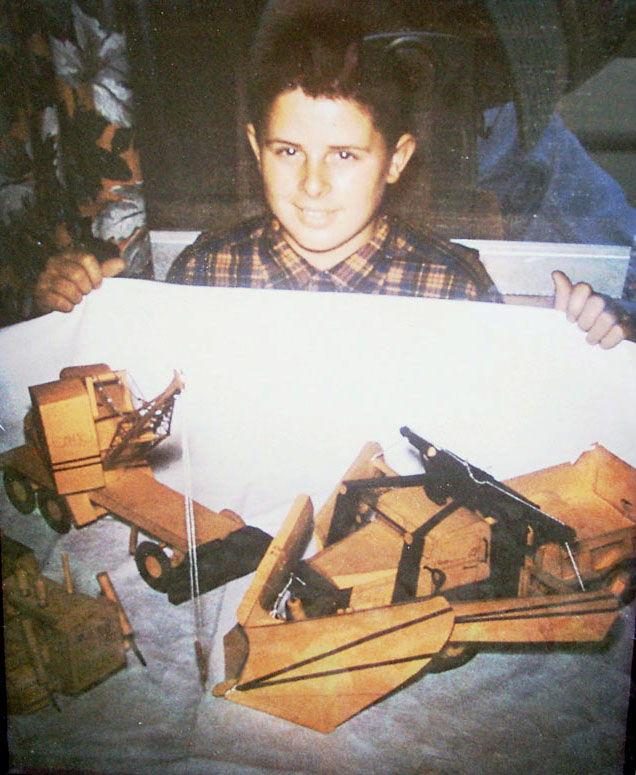

Making Truck Models at Ten

Heim grew up in Lovell, Maine, and at the age of 10, began making astonishing truck models out of wood and cardboard. Fred noted, “My father was the road commissioner of Lovell, Maine, and at that time, I was more interested in designing and building models than I was with scholastics. I was able to look at something in a brochure and then build it. We didn’t have cameras back then.”

His childhood model dimensions always surprised adult craftsmen, as they were dead on specs to their life-sized equivalents. “I’d made them out of construction paper and LePage’s glue, and the plows, wings and the dumper would all work,” he said of his first models.

Heim is entirely self-taught. “I was always fascinated with wood. I knew, at a very young age, that I would always be working with wood,” he said.

Again at age 10, Heim began building 10′ Chris-Craft Boats from a kit. His father bought a boatyard in the early 1950’s, and he began a boat building business in his own yard—canoes, rowboats, and canvas-covered boats. He went to the Newton Trade School and built a boat there some 51 years ago at age 18, and, added proudly, “No one’s done it since.”

By age 20, Heim was married and building a career in boats—20′ cruisers, hydroplanes, world cup boats. “My last boat was a 38-footer with a V-bottom and a WWII PT boat engine—a 2500 cubic inch supercharged V-12 putting out 1350 horsepower,” noted Fred.

Along with 40 years of boat building, Heim had a hand in constructing more than 450 new homes. Fred retired in 2005 as President of Oakwood Construction, a builder of custom homes.

Building the Peterbilt

“I’m finishing a boat, I looked up and this truck is sitting there,” said Heim. “I thought, ‘Wouldn’t it be nice if I built that truck at half-scale, and get in it and motorize it.’”

After measuring a full-size Peterbilt, Heim made a cardboard silhouette of the truck cab, “to see if [he] could get in.” It was painful, but he could.

“It’s still painful to get in and out, but I do it,” he laughed. “I wish I had a dollar for every time someone said, ‘You can get in there?’” Once the cab was set, Heim dug into his wooden Peterbilt, unlike any in the country.

“My intention was to put a battery in the truck and have it run by a golf cart motor in the rear end,” he said. He started with aluminum frame rails, cut out of a stock. A friend in the trucking business told him he needed a Diesel engine, so he found a small, 26-HP Yanmar Diesel with three cylinders. It runs through hydrostatic drive connected to a 12” driveshaft.

Water-cooled, the truck has a 12-volt electrical system for the fan. The truck is fully gauged, the windows go up and down, and it has a hydrostatic transmission and hydraulic brakes that also work.

There is a fifth wheel that looks and works like the real article, and the interior of the fiberglass cab is fully upholstered. The engine, mounted to the rear of the cab so Heim can put his legs under the hood to drive it, is enclosed with the typical wet system that one would see on a dump trailer chassis.

The 13-gallon fuel tanks are made out of 26-quart aluminum lobster pots. Heim cut them in two at 6” each, and formed the aluminum fabricated center. He welded under strap supports for the two fuel tanks. The air cleaner tops were 7” pizza pan covers. Cab lights are turned from billet aluminum, and the headlights are classic Harley-Davidsons.

All of the interior braces and supports are made from mahogany. “Every rivet is half-scale, and you can count every single rivet to see that the number matches the number in the original,” said Heim.

But that isn’t all. Heim’s attention to detail went far beyond just the working half-truck. Both tractor and low-bed trailer have air suspension.

The trailer dump is a Hill 26’ replica, also made of wood and aluminum. All of the aluminum on the tractor and frame was powder-coated, instead of spray painted. “It looks like it’s brand new and 100 years old at the same time,” beamed Heim.

The dump body of the trailer, so metallic in look, fools virtually everyone. It is really made of Honduras mahogany.

“The first thing people do is tap it,” laughed Heim. “They have trouble believing it’s wood. A lot of people will say, ‘It’s a kit!’ No, it’s not a kit. You can’t buy it. There’s only one half-scale in the country that we know of and this is it.”

With the Peterbilt pulling the Hill custom-built trailer, its Diesel engine puffs grey smoke out of its twin stacks. At night, it’s even more impressive, with all 98 of its lights flashing.

After a year’s work, Heim’s Peterbilt got immediate attention. He brought it to the American Truck Historical Society in Brooklyn, CT, and drew an overwhelming crowd. A writer from a national magazine wrote of his work. Soon, he was at trade shows and exhibitions, gaining national notoriety.

Project Two: A Cat D8R

The next year, 2005, Heim, inspired by his success, was at it again. He made a half-scale Cat D8R with a Rogers trailer, all made of aluminum. The Cat undercarriage was a real challenge. The frame is boxed mahogany, and the sprockets and idlers are all turned mahogany.

He fabricated the track links of Corian with PVC pins and bearings. Each track has 88 links. Axle shafts are aluminum, but the track pads are made of marine mahogany plywood. While this model doesn’t run, it all works. The trailer has air suspension, and the tracks and bogies move and roll like the real thing.

Again, the interior is upholstered with too many details to name. The rig really turns heads on the highway, especially with its “Wide Load” sign, which isn’t really all that wide.

While the D8R is static, the Rogers 60-ton, tri-axle drop-deck trailer is just like the real one. The Rogers Co. itself provided Heim with graphics, mud flaps, plans, and photos to give him all the details he needed. The trailer, completely fabricated from aluminum, has decking planks of solid mahogany with operating running lights.

When Heim took this pair of beauties to the National Toy Truck N’ Construction Show in Indianapolis, IN, the remarks were off the charts. It was worth the long drive to Indianapolis, he said. Everyone enjoyed seeing the display in person after seeing it in the magazine, ToyTrucker.

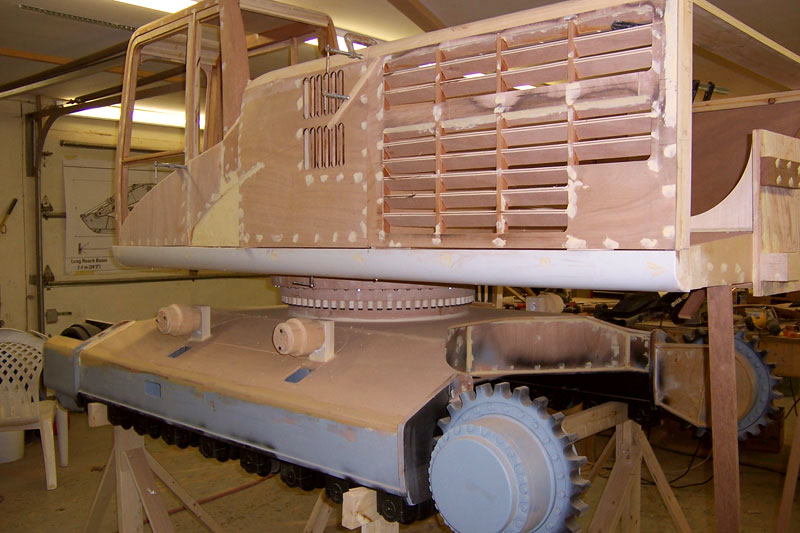

This photo was taken in the early stages of the excavator project. The model was taking shape in mahogany. Metal parts were also fabricated for areas in need of extra strength or cross-sections.

Project Three: A Cat 345C L Excavator

The next year, 2006, Heim created another extraordinary model—his half-scale Cat 345C L excavator. Again, a labor of love in mostly wood and aluminum, the Caterpillar model can rotate 360 degrees over its undercarriage. Hydraulic cylinders are made of PVC tubing and aluminum. For the tracks, Heim had to produce 104 PVC links at nine pieces per link.

The 18” pads are made of wood, but the idlers and bearings are also PVC, and like the real ones, are adjustable.

The “real” 48” bucket is, of course, only 24” in the replica. It features removable teeth and real-style wear pads. Heim said he used 20 sheets of Okoume mahogany to complete it.

The cab features an opening door and the precise interior detailing matching its inspiration. Heim hand-carved a female “operator” out of white pine.

Project Four: A Cat 980H Wheel Loader

In 2007, Heim greeted his increasing fan base with his fourth half-scale project—a Cat 980H remote-controlled wheel loader.

Working in his spacious garage workshop in Marlborough, Heim tried to top himself this past winter building a new addition to what has turned from hobby to a small (half-scale) cottage industry. How? A working remote control to handle the more intricate engineering.

The tires on Heim’s new Cat represented the biggest challenge, so that’s where he began his work. Rubber? No, marine and solid mahogany—3’ in diameter, and 15” wide with treads cut from 2 x 6 fir.

Not solid, Heim devised a system of interior baffles to keep the weight down, and to add strength to the tires. They are screwed on and filled, but resemble real rubber.

It took 12 gallons of automotive Bondo to complete them. The only rubber is used on the bands slipped over the center of each tire to protect them from cracking when the machine is moving. Once he solved this problem, Heim moved to the body, again using marine mahogany, aluminum, and fiberglass, with aluminum in the main frame.

The engine is a 6.5-HP Tecumseh with a hydraulic pump and transmission. Six custom-built aluminum hydraulic pistons operate the bucket, arms and steering.

The remote control lifts and turns the bucket, starts the motor, and moves the wheel loader in all directions. The hood, cab and fenders are also mahogany, with upholstered seats inside, an adjustable steering column, and sliding windows. The realistic quality staggers the viewer studying every corner and each inch.

With this sixth piece, Heim said his full-time hobby of half-scale work is done. “I’m trying to sell all four to a museum. All have to go at one time, as a set,” he said. “If anyone is interested in buying the collection, contact me.”

—James A. Merolla

In January of 2010, Fred started building this 1/12 scale model of a 75’ Expedition Yachtfisher made by Nordhavn, called the Crosswinds II. Fred made a number of model boats to go along with the full-size ones that he built for a living.

Articles and Videos on Fred Heim

Read an article about Fred from Toy Trucker and Contractor.

Read another article about Fred in Wood magazine from May, 2010.

Watch a short YouTube clip below showing Fred’s model wheel loader being driven into a trailer.

Watch a video of Fred’s first launch of the 1/12 scale Crosswinds II yacht, which is pictured above.

Watch a video of the construction process for another one of Fred’s 1/12 scale model yachts, the M.V. Olympus.

Additionally, you can view more photos of Fred Heim’s incredible 1/2 scale construction equipment, along with a number of other projects.