A Jewelry Craftsman With a Love for Harley Engines in Miniature

Introduction

Back in the early 1990’s, Harley-Davidson had a precious metals contract with Stamper Black Hills Gold. The company marketed a series of very small pins, representing Harley engines, which were designed by Bryan “Fence” Freund. Larger versions of the mini engines were attempted, but they weren’t practical for production. The cooling fins worked too efficiently, and could not be cast. However, that didn’t stop Bryan from continuing to craft unique miniature Harley engines.

“Clearly, mistakes are a key to learning anything worthwhile, but try to make the STUPID one’s as a rookie. They are easier to digest when you have a good excuse.” —Bryan Freund

Bryan’s wife, Rusty, was extremely skilled at business and negotiation. She managed to get us an order for a 3D Panhead replica from the flat Sportster engine, and the much smaller pin size, as samples of Bryan’s work. The couple continued to learn every aspect of jewelry manufacturing (Bryan’s vocation), and bought their friend and neighbor’s house next door. The house was zoned for business in 1994, and Freund Jewelers was born.

Before that, they had been known as Fence’s Custom Jewelry, using Bryan’s old nickname, Fence, as a trademark. Fence is Bryan’s road name, and many of his friends only know him by that name. Recently, Bryan had cast the last piece for his new Evo engine (Harley’s newer “Evolution” model), and also built a micro version—his latest piece.

Being retired at the time of this writing because of a rare brain cancer, Bryan had no desire to continue manufacturing items for sale. He was still working on the little Harley engines though. Bryan noted, “Most of my work has not been motorcycle art actually, but most folks find the little engines quite impressive. I never had any schooling in the arts. In fact, I was a garbage man for 20 years. I taught myself through perseverance and practice in my spare time.”

Bryan did note that he would like to thank Tim McCreight for his excellent book, The Complete Metalsmith. Bryan largely credited the book for helping him to become a jeweler. He referenced that book many times for over 20 years. The following is his story, in his own words, along with photos of his work.

One of Bryan’s tiny Harley-Davidson vintage Panhead engines, made from silver. This isn’t just a single casting, the mini engines are assembled from hundreds of individual parts.

A Love of Metalworking Leads to a Thriving Side Business

By Bryan Freund

I was born in 1961, in a family of craftsmen and woodworkers. I loved to draw, but was always drawn to metalworking, and then motorcycles or anything that flew. (We had an Indian Motorcycle dealer down the street from our rented farmhouse.) As a kid I built a lot of plastic models, but the wooden Guillow’s model airplane kits really were a favorite—in spite of the fact that rubber power never worked very well for me.

On my 18th birthday, I found myself in boot camp in the US Air Force, wanting to build real aircraft and get to the mountains to grow up. After basic training, I began my only formal metalworking training—3 or 4 months at Chanute AFB in airframe repair. Then I got assigned to Williams AFB in Arizona, which had the distinction of having the lowest re-enlistment rate of the entire Air Force. I learned that much later on, but it was in the mountains of Arizona, so I was delighted. I got into trouble fast, and ended up permanently stationed there.

My artistic abilities couldn’t be bottled up, so I began making knives and other artistic pieces hidden under the bench. I really loved the martial arts, and made dozens of throwing stars. As good as my metalworking skills were, my attitude was equally bad, so in 3 years I was honorably discharged a year early. I held down a lousy job in Arizona for a while before moving back to Illinois. After returning, I drove a truck for a family friend’s business. Then, another trucking job led up to a career in the trash industry. I became a garbage man.

In my spare time, and with my new knowledge of metalworking, I built a decent polishing machine. I saved any silver tableware I found, and hammered it into sheets. With crude hand tools, I began making earrings and rings. I bought a jeweler’s saw at an estate sale, and then my most treasured book, The Complete Metalsmith.

One of Bryan’s Harley Evo engines displayed on a rock. This engine required as many as 400 individual pieces at Bryan’s last count.

After a few years, I met my wife of 28 years, Rusty, and set up a desk studio where I set out to learn to solder. Knives were my goal at first. I wanted to create custom knives, but mistakenly bought jewelers equipment thinking it was what I needed. Wrong!

We moved again, and I learned to solder silver thanks to Mr. McCreight’s book. Then, in 1986 I cast my first pieces via a hot plate flower pot. The next week we were at a jewelry supply store buying a burnout oven, polishing lathe, etc. I was hooked, and began making all kinds of assorted pieces that were sold at low prices.

I learned to set in bezels, and bought inexpensive (at that time) “jelly opals.” I scoured every page of Tim’s book, and practiced every technique in it every chance I could get. Engraving and bead setting fascinated me. I collected carbon steel knives to make into gravers, and saved rhinestones to bead set into silver—reasoning that they must be difficult to set, being glass. They were perfect practice stones, and found for free in the garbage. In a few years, I fabricated my first miniature motorcycle engines for friends. A Harley-Davidson 1911 single-cylinder engine was the first one, and then a later model Knucklehead V-twin.

I continued to buy and collect tools of the jewelry trade, and improved my skills. The flex shaft was a godsend to me, and really sped things up. My work soon became somewhat popular among friends. I experimented with rubber molds soon after, and began to create a line of biker pins and rings that my wife and I sold at swap meets from a wooden case. I also began to tinker with gold occasionally, albeit rarely, at that time. By 1990, my work was pretty good in silver, and practice is what I did. I feel that I benefited greatly from having no formal training, as that let me master bead setting first—which I loved, and always will.

My methods were almost entirely fabrication at first, and bead setting became my signature style, so to speak. Having been a Harley fanatic since buying my first Harley at 21, the Sportster engine was my first really detailed engine-related piece. It was made just for kicks, but Rusty took it to Harley-Davidson, and they ordered a Panhead. Of course, I was thrilled to make it, and in a few months I completed that model and a couple much smaller versions.

Shown here are a couple of the special Harley engine pins that Bryan created. The newer Harley Evolution engine is on the left, and an older style Panhead engine is on the right. A smaller Evo is in the bottom left corner. A US quarter and a copper scale provide size reference.

Starting Out With Simple Tools

My shop’s tools started very crudely: a homemade polishing motor without a filter, hand files, all kinds of pliers, any useful tool I found, every hammer I could get, a desk for a bench, and plumber’s torches and anvils. After that first casting, we got a Newcraft burnout oven, a Pro Craft vacuum casting table, and my engraving block. Files have always been my primary tools, compared to all other jewelers I’ve met. I find they transfer directly to the metal through feeling, so I can control them with great ease. Even #6 cuts are common on my bench. After going into business all kinds of other tools were needed, and like any repair or bench jeweler, the collection of small tools grew.

Gravers also became my must-have tools. Engraving is an art I admire greatly, and only really have the most basic ability with, compared to a master engraver. However, being necessary to bead setting—the style of setting I consider superior to all others—my abilities with engravers improved over the years, though they are in no way complete. The fanciest tool I have is probably the Smith torch, which I had wanted for years, only to find that I don’t like it at all.

Harley Evolution engines in various sizes, modeled in silver by Bryan. This photo shows that each tiny engine is made up of many sub-assemblies. Each of these sub-assemblies are made up of many more individual parts.

Tricks of the Trade

One of my “tricks” is to visualize everything I work on as being much, much larger in my imagination. I also utilize my imagination as much as possible to rehearse my next steps, usually a couple steps in advance. I would love to share my techniques with any students. I don’t believe in keeping any techniques secret. We were all beginners once, and we all continue to make occasional mistakes. Mastery is the ability to cover them up as if they never existed. This is something I learned from years of repairs.

Quality Work and Imagination Combined

Quality has always been #1 in my pieces, even at the expense of sometimes being rather heavy. I build things to last for a lifetime, and adhere to the motto, “Quality isn’t cheap, it’s priceless,” although our prices were always modest. The art is an endless journey of learning for me, constantly picking up new tricks, or finding a new and better way that was somehow simply overlooked. Surely, I will continue to create new pieces of metal art as long as the Lord allows me. I believe it is a God-given gift, and my job is merely to practice and learn to use it.

Thoughts on Bead Setting

Bead setting is somewhat rare in today’s market. It is always one-of-a-kind by nature, time consuming, and for many jewelers aggravating at best. It is very unusual to learn stone setting, starting with the most difficult of traditional methods, from what I’ve been told at least. It’s like learning to fly a jet before logging hours in a Cessna 150, maybe. If you tried hard enough and were crash proof, in theory at least, you could do it. From my experience, though, I don’t think that’s a major exaggeration. So, even compared to my engines, I think bead setting is equally demanding of craftsmanship.

From Silver to Gold

Almost overnight, gold became my primary metal. While focused on one-of-a-kind items at first, we soon had a thriving business including repairs and diamond sales. We focused on teaching our customers about quality and what to look for, and then letting them decide where to buy. The old line of biker jewelry became second fiddle at best.

Gold, I soon discovered, was a lot different than silver, and I quickly became familiar with it in a “trial by fire” manner—having no actual choice. Repairs were an important part of our business, though I really despised doing them, as it was never my work and very often not of high quality. However, it was priceless to the owner, so even the least valuable repair was treated with all my craftsmanship, as if it were a custom piece that I had made.

A small Evo engine sits on a quarter, and a tiny Panhead engine on a dime. A tiny silver skull can be seen on the quarter at the top.

A Brain Tumor Means Major Life Changes

For a decade we had a nice family style business. This kept us both extremely busy—Rusty running the store, orders, inventory and all paperwork, and me handling the mechanical end of things, and repairs after work. That went on until 2005, when I woke up in a hospital bed. The last thing I remembered was driving the roll-off (garbage) truck. Then I discovered that, like our neighbor and friend Kurt who sold us our home/business, I also had what was soon confirmed to be a brain tumor. To say this caused problems would be a major understatement, but after six months I did return to driving. For just short of a year I kept my old job, but I was soon let go, and then went on a long round of chemotherapy.

Afterward, I could not manage to do what I had before, and we soon had to close our store. Just before that, another neighbor who moved to Arizona had visited the store, and told Rusty that her husband Frank had died from a brain tumor. That made both neighbors victims of this terrible disease. We contacted a lawyer and began a lawsuit, as our only neighbor a mile to the north was a chemical plant. Within a year, over 20 others with tumors were part of the suit, which eventually grew to over 30 victims in a neighborhood of 500 homes, and part of another across the lake. After a short while, I was forced into retirement and disability, collecting a pension from the garbage company.

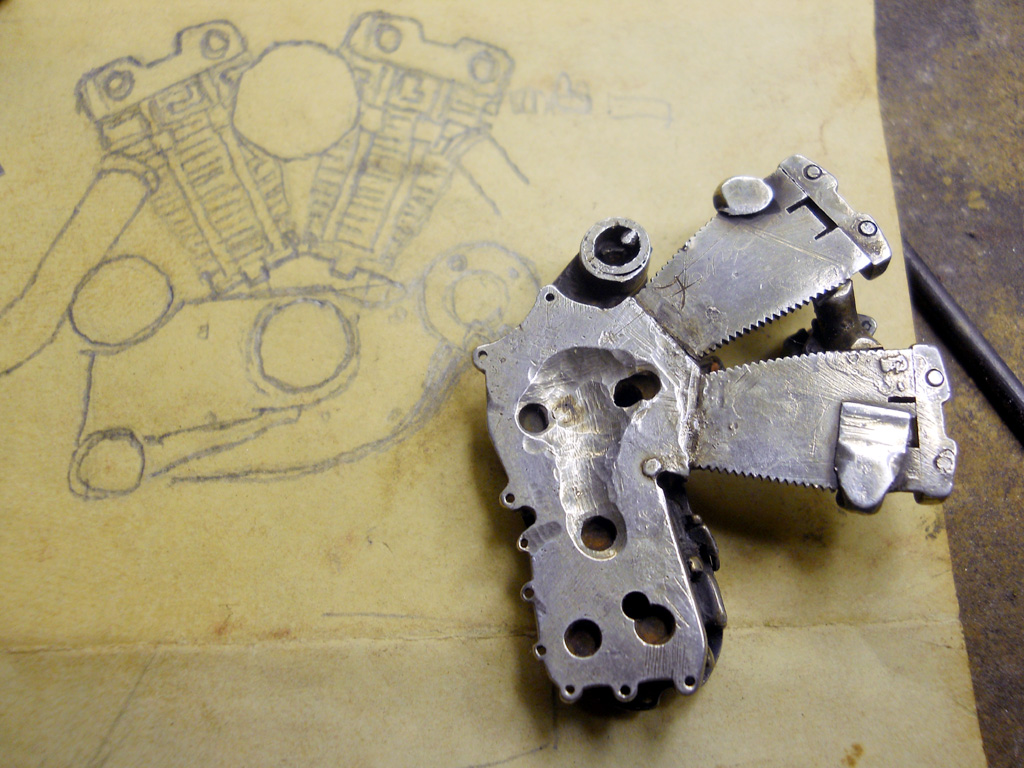

Pictured here is the back side of the Sportster engine, sitting on the drawing that Bryan made to work from.

From a Hobby to a Business, and Back to a Hobby

Then, I resumed my metal working as it had begun—as a loved hobby. The store was very busy, and a godsend for my wife, as with a bad heart she had to have a very flexible operation. So, every weekend I made myself available to evaluate any tricky repairs, or answers to questions on any custom orders. My old work, engines included, stayed tucked in a drawer, rarely seen by anyone. The reactions to it were very mixed, as most people had no idea the amount of work required to fabricate them.

Eventually, one of the two chemical plants settled with us out of court, so we were able to save our home, but the business was over. Soon I bought a computer, and began to share pictures of my old work on Facebook. Only then did I realize they were perhaps exceptional, and an old friend suggested I send some pictures to your incredible museum. Now I am able to tinker with my equipment and ideas like a hobby, as it all began, whenever I am feeling well enough—and again, I LOVE to work on my projects.

“Imagination is more important than knowledge.”—Albert Einstein

The above quote is particularly true for me. Visualization is a big key to how my things are created, since I began my metalworking with rather crude tools and equipment, at least at first. I even started out setting diamonds with no more than a pin vice and homemade gravers, although that would require many more tools in short order. My shop by today’s standards is very simple…just the basics really. It’s what is in our heads and hands that really matters in my opinion. All of my more intricate work is built many times in my imagination before my hands get involved. I feel, and often say, “Art is born of pain, if none other than the idea trying to express itself.” For me it’s entirely true.

—Bryan Freund

Bryan’s production is now limited, but he still enjoys the creative process and making use of his skills. View more photos of Bryan’s craftsmanship.