This Craftsman’s Paper Airplanes Aren’t Like the Ones You Made as a Kid.

Biography

This biographical information is a condensed version of Mr. Briggs’ background, courtesy of Paperwarplanes.com.

When Huntly was a child, he saw the motion picture Wings (1927), and Howard Hughes’ Hell’s Angels (1930). These films inspired him and his older brother, Stephen, to start making paper airplanes and coloring them with crayons. From that point onward the brothers were mystified by aviation, and became lifelong enthusiasts. At ages 18 and 20 respectively, both of the Briggs brothers started their aviation careers at Lockheed Aircraft Co. They got in just before World War II, building Hudson Bombers for Britain, and P-38 fighters for the U.S. Army.

Shortly afterward they would both join the military, with Stephen becoming an Army pilot and Huntly a Navy aircraft technician. After their service was completed, each brother remained close to the aerospace world doing writing, illustrating, and advertising for various companies. They never strayed far from their passion for aviation. Huntly earned his college degree and pilot’s license on the GI Bill, and subsequently flew light aircraft for business and pleasure for thirty years. Ironically, many years after seeing those first airplane movies, the Hughes name would come back into Huntly’s life. In fact, for 33 years he would provide advertising services to the Hughes Aircraft Company.

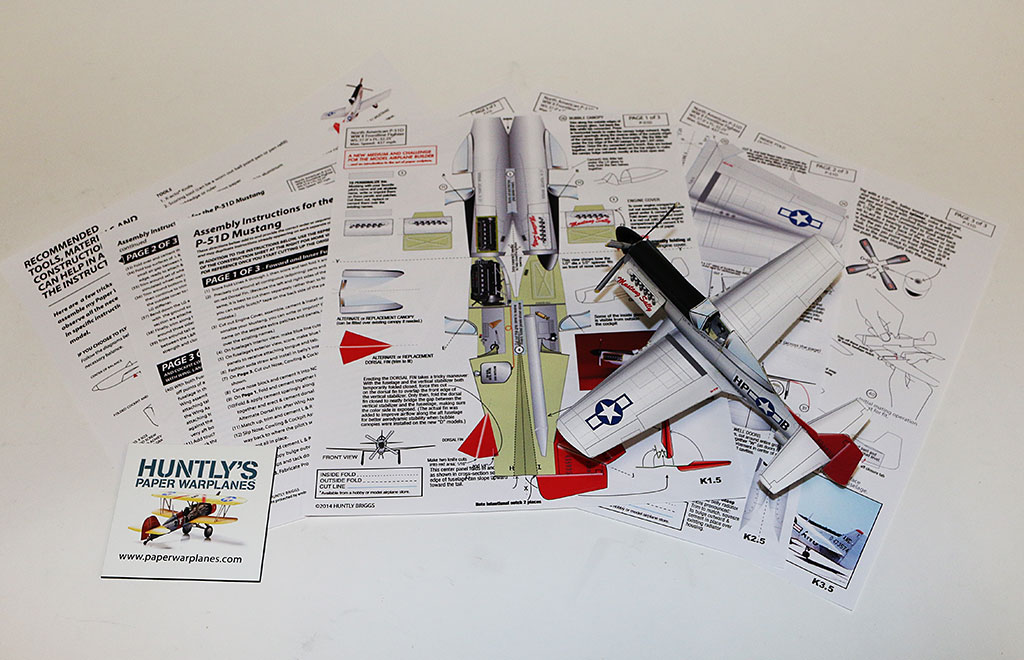

Over the years, Huntly became an avid fan of vintage airplanes, and a student of military aviation history. His love of paper airplanes was rekindled when Scientific American magazine hosted a worldwide paper airplane contest around 1970. Later on, after discovering computer graphics, he made a hobby out of his own paper airplane constructions. Huntly made these planes from two or three folded sheets of letter-size paper, with graphics printed onto them. You can view some of the planes with the printed sheets from which they are assembled both here and on Huntly’s own website.

Now, these 3D flyable paper models had evolved from simple fold-and-cut gliders, and Huntly focused mainly on biplanes. The biplanes represent early development in aviation, and they mark the era which truly captured Huntly’s passion for aircraft. From his perspective as an aviation buff, these planes were like birds in nature—graceful, colorful, and beautiful. However, biplane configurations certainly didn’t lend themselves easily to paper airplane construction. However, that would change once computer graphic programs made it possible to design and print elaborate construction layouts.

Plans for the Curtis P6E, and North American P-51 Mustang are shown above alongside the finished models. Plans consist of three sheets of color printed paper, which you can cut out and fold. They also include detailed instruction sheets with tips for turning out models that look as good as Huntly’s.

Moving forward, these computer programs made it practical for Huntly to refine the plane’s design, the positioning of its elements, and their interworking relationships. All the while, they also added intricate detail and color combinations to the models. As a result, Huntly would have far fewer limitations when it came to the details and designs for his models. Moreover, it was all made possible thanks to the kind and patient computer instruction of his younger brother, Alfred, a well-established graphic designer.

This is a model RAF-S.E.5 (British) from WWI.

Model Kits Are Available From Huntly’s Website

Huntly Briggs was 93 years old when he visited the Craftsmanship Museum. During that visit, he donated some of his kits, along with a few finished models for display. As of this writing, he is still designing and building them.

View more photos of Huntly’s beautifully crafted paper airplane models.

Read about one of Huntly’s interesting design career inventions, the “Automatic Highball Machine.”