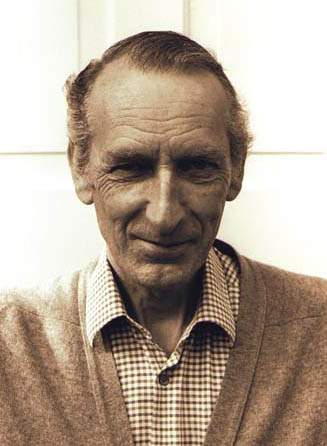

1924— February 16, 2021

Updating Old Clock Designs to Distribute for Others

Introduction

John Wilding’s interest in clocks began early in his schooldays, after reading the horology section of the Encyclopedia Britannica. He also made frequent visits to the school clock (strictly out of bounds), which was a fine Thwaits and Reed striking movement. This, along with further reading in the field, stimulated John’s interest in clocks.

For about five years, John was pulled into WWII. After that, he married and went into agricultural engineering. John used a lathe in that business, and realized that he could also make a clock on the machine. In the early 1950’s, the only drawings and instructions for making clocks were found in Model Engineer magazine.

On the pages of Model Engineer, famous amateur clockmakers like George Gentry, Claude Reeve, and John Stevens wrote about their work. So, John started making clocks from their descriptions, and later made his own contributions to the subject—in both Model Engineer and the Horological Journal.

This 8-day weight driven wall clock was the first that John made for his instructional series. The simple design made it very popular, and John’s book on its construction went through several editions/reprints. This clock led many craftsmen toward an interest in clock making.

Getting His Start in Clockmaking

As a result of his efforts, the editor of the Horological Journal invited John to write a constructional serial for the publication. The serial would describe how to make a simple 8-day weight driven movement, without buying any ready-made parts. This would be the start of some thirty constructional serials that John wrote, all of which were compiled into books.

John’s first 8-day clock was quite a breakthrough for the Horological Journal, as very few professional clockmakers at that time had a lathe the size of the Myford ML 7. They may have had an 8 mm collet lathe, but most “High Street” repairers did little more than clean clocks. Major repairs were typically carried out by one of the parts manufacturers in Clerkenwell.

If a clock needed a pair of pallets, the High Street shop would send the clock plates, pallets, escape, and third wheel up to the parts manufacturer. The manufacturer would do the complete repair, and the remainder of the movement was assembled and then passed to the customer.

At that time, there was also a great deal of secrecy in the trade. It was difficult for an amateur to learn certain processes. On one occasion, John went to purchase tools from a retailer in Clerkenwell, who asked if he was in the trade. When John said no, they refused to serve him. He wanted a mainspring winder, but they wouldn’t sell him one. John went home and borrowed Claude Reeve’s winder to make his own!

This Congreve rolling ball clock has always captivated the mechanically minded. The captive ball endlessly traversing the table, from one end to the other, has a mesmeric effect on those watching. It was popular to place one of these in the window of a clock or jewelry shop, as it always attracted an audience. It’s not a particularly accurate time keeper, but fun to build and watch.

This was one of John’s early versions of Galileo’s Escapement Clock. John updated his plans for this clock to include two motion work gears outside the frame, along with an hour hand and dial for indicating time. The mainspring only runs for four hours, but it can also be converted to weight drive with autowinding.

Entering the Trade Full-Time

Shortly afterward, John’s circumstances altered and he sold his home in Sussex. The new property was not ready to move into, so he went to work in a London repair shop. John recalled that it was a wonderful experience. The foreman was Ron Rose, and there was nothing he couldn’t do when it came to clock repair. John learned an enormous amount there. When he left, he worked for a wheel cutter for a short period, which was also a valuable and interesting experience.

Once he was finally back in Sussex again, John continued on as a full-time clockmaker and writer. He produced an average of one new clock every year. He also did repair work, and it was from those clocks that John compiled four volumes on the repair of antique clocks.

John was always fascinated by the inventions of other clockmakers, many of which had fallen by the wayside. When he would read about these inventions in some of the early literature, John would make them to fit into his clocks—giving them a second chance.

An example of that innovation can be found in John’s Henry Ward full striking clock, which does not require a second wheel train. John also made the perpetual date work for a longcase clock movement with the usual date ring. Both of those older inventions are described in John’s book on the 8-day wall clock, and they function perfectly.

Designed to be constructed on a small benchtop lathe, this 16th century style clock is an easy project for beginners. It employs the verge escapement, and has a single hour hand. It runs for 30 hours on a winding. To get full running time, the clock must be mounted at least six feet above the ground to allow enough room for the weights to descend.

This clock is based on the Ever Ready electric clocks that were manufactured in the early 1900’s. A unique feature is the motion of the pendulum, which swings backward and forward instead of side to side. The operation is based on the Scotts notched tooth principle, which is similar to the Hipp system.

At some point, John was told about the Aaron Dodd Crane “daisy wheel” motion work. He found this fascinating, and promptly fitted one to his egg timer clock, together with the MacDowall single pin escapement.

Newcomers to clockmaking often imagine that a high precision and expensive lathe is essential for this work—but this is quite wrong. John made many clocks on small hobby lathes, including all of the wheel cutting. Manufacturers would often loan their lathes to John, knowing that the publicity from his publications would benefit their sales.

In 1986, John was elected a Fellow of the British Horological Institute (FBHI). He was awarded the Institute’s Barrett Silver Medal in 1998.

John’s books were published by RiteTime Publishing Ltd. For a full list of the books Mr. Wilding wrote, click here.

Additionally, view more photos of John Wilding’s masterful clocks.

This is a very unusual and spectacular clock, with its contra oscillating compound pendulums. The bobs of the pendulums take the form of scissor handles, as do the hands and winding key. The Scissors clock runs for a week on one winding, and the unique pendulum action offers a great visual. This clock can also be built on a small benchtop lathe.