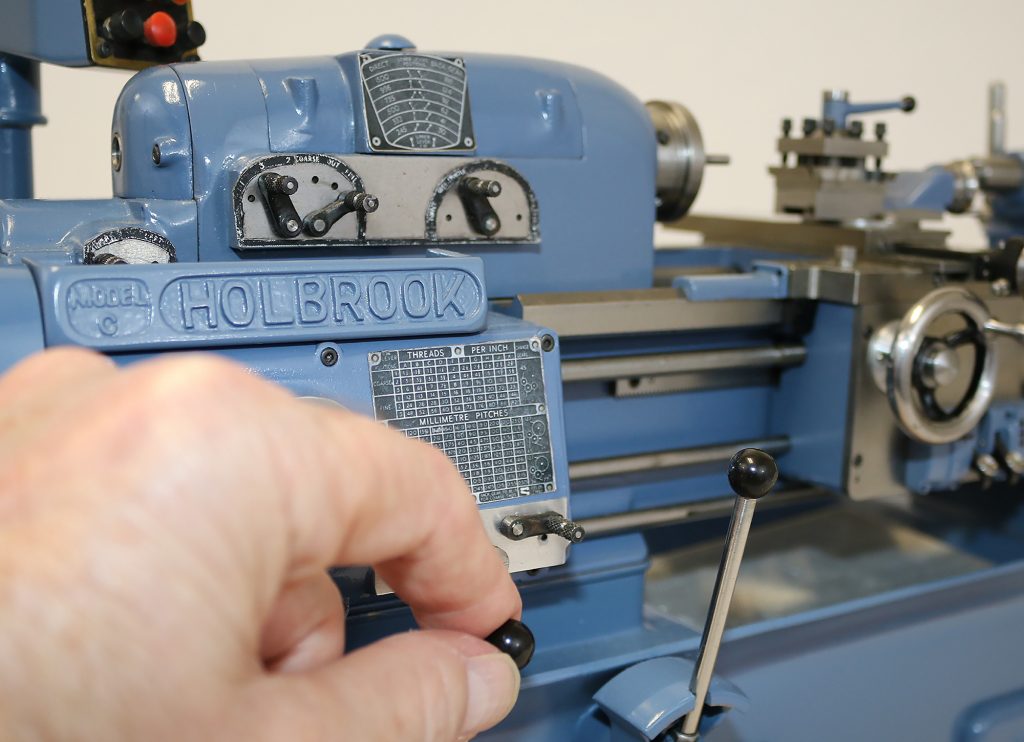

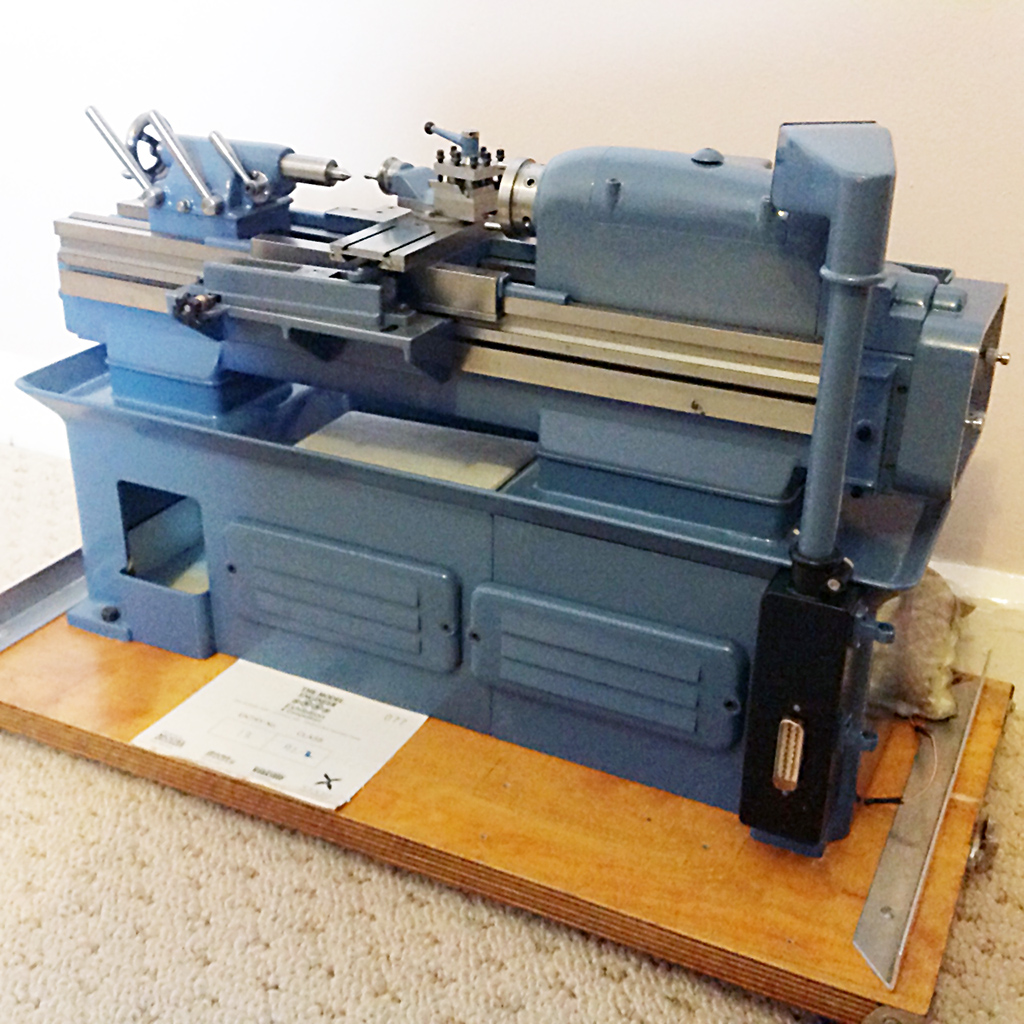

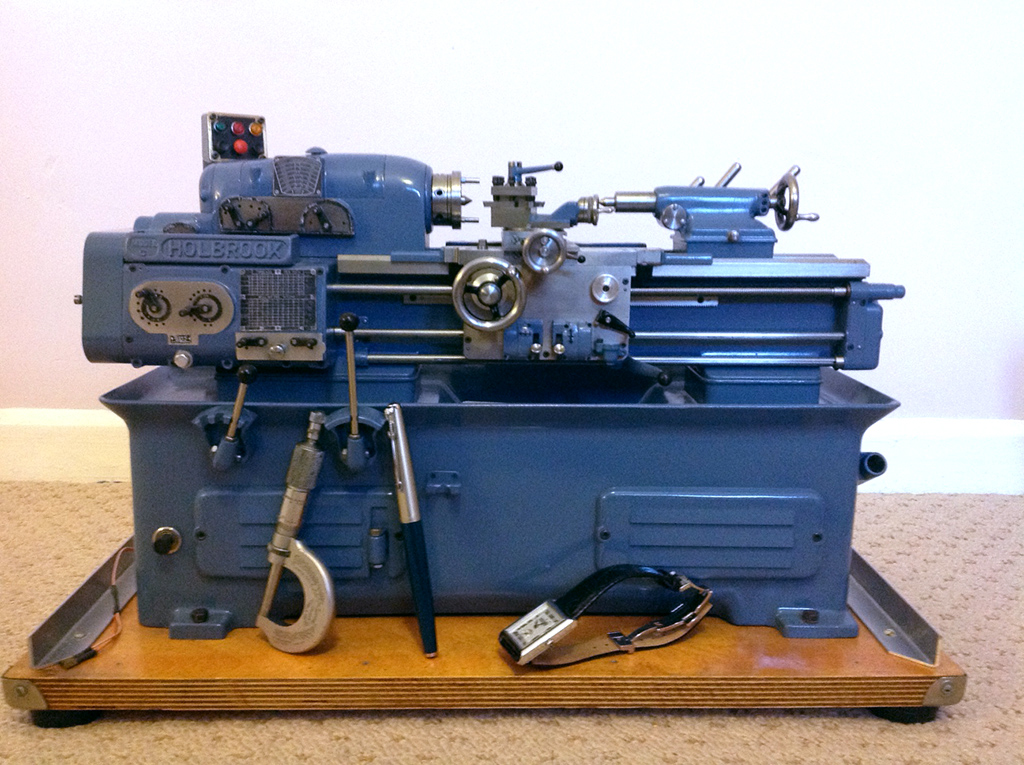

Alfred Mellows worked on this project—a functioning 1/6 scale Holbrook Model C lathe—for many years. Initially, it was not going to be a working model, but at the prodding of workmates, Alfred decided to make the tiny lathe work. This became a lifetime endeavor, spending time whenever he could to perfect the machine’s features over the years. After retirement, Mr. Mellows converted his garage into a workshop with the necessary tools to complete this ambitious project. He finished his work on the lathe only months before passing in 2003. Find out more by reading the complete article about Alfred and his Holbrook Lathe.